News

-

China’s 75th National Day: Challenges and Opportunities for the Screw Machinery Industry

The 2024 National Day holiday has significantly impacted China’s screw industry. As an essential part of the manufacturing sector, the screw industry is closely linked to related fields such as plastic extrusion and injection molding. While the holiday offers companies a brief respite, it a...Read more -

Jinteng Constructs Rainproof Cloud Corridor to Safeguard Quality and Boost Efficiency

Recently, Jinteng initiated the construction of a significant infrastructure project—the Rainproof Cloud Corridor. This project aims to provide efficient protective measures during the transportation of screws from the processing workshop to the quality inspection center, ensuring that the produc...Read more -

JINTENG Welcomes Indian Clients for Factory Visit, Strengthening Ties for Future Collaboration

Recently, JINTENG had the pleasure of hosting a delegation of clients from India for a factory visit, marking a significant step in fostering closer business ties. The visit was an opportunity for both sides to engage in in-depth discussions about future cooperation and explore potential areas of...Read more -

Officials from the Foreign Economic Affairs Office Visit Jinteng to Promote the Benefits of the APEC Business Travel Card

On August 15, 2024, Jinteng welcomed representatives from the local Foreign Economic Affairs Office (FEAO) for a productive and friendly discussion about the advantages and uses of the APEC Business Travel Card. As a leading international trade company specializing in screws, Jinteng has establis...Read more -

Masterbatch production of overseas branches

RAINBOW PLASTIC BEADS COMPANY LIMITED is a subsidiary of JINGTENG, located in Vietnam, specializing in the research, production, and sales of masterbatch. We offer a diverse range of masterbatch solutions widely used in the plastic industry, including packaging, home appliances, and automot...Read more -

Regular visits to overseas branch offices

“DUC HUY” is our overseas branch in Vietnam, officially named Vietnam “DUC HUY MECHANICAL JOINT STOCK COMPANY“ Regular visits to overseas branch offices are vital for strengthening communication, collaboration, and operational efficiency across the entire organization. Th...Read more -

Company Team Building: Hiking, Go-Karting, and Dinner

In today’s competitive corporate environment, fostering strong teamwork and cohesion among employees is essential for sustained success. Recently, our company organized a dynamic team-building event that seamlessly integrated hiking, go-karting, and a delightful dinner, providing a memo...Read more -

Jinteng Screw Barrel – The New Engine of Industrial Revolution

In the wave of modern manufacturing, Jinteng Machinery Manufacture Co., Ltd, once again leads the industry trend with its innovative technology and outstanding product quality. The design concept of the new generation of barrels stems from a profound insight into market demand and a forward-looki...Read more -

Zhejiang Xinteng Intelligent Technology Co., Ltd moves to new factory

Where is the confidence in extending the industrial chain? Is it the right way to go? Check out the report: This is the new building of Zhejiang Xinteng Intelligent Technology Co., Ltd. Steel structure of the building has been completed. Under the aerial camera, we can s...Read more -

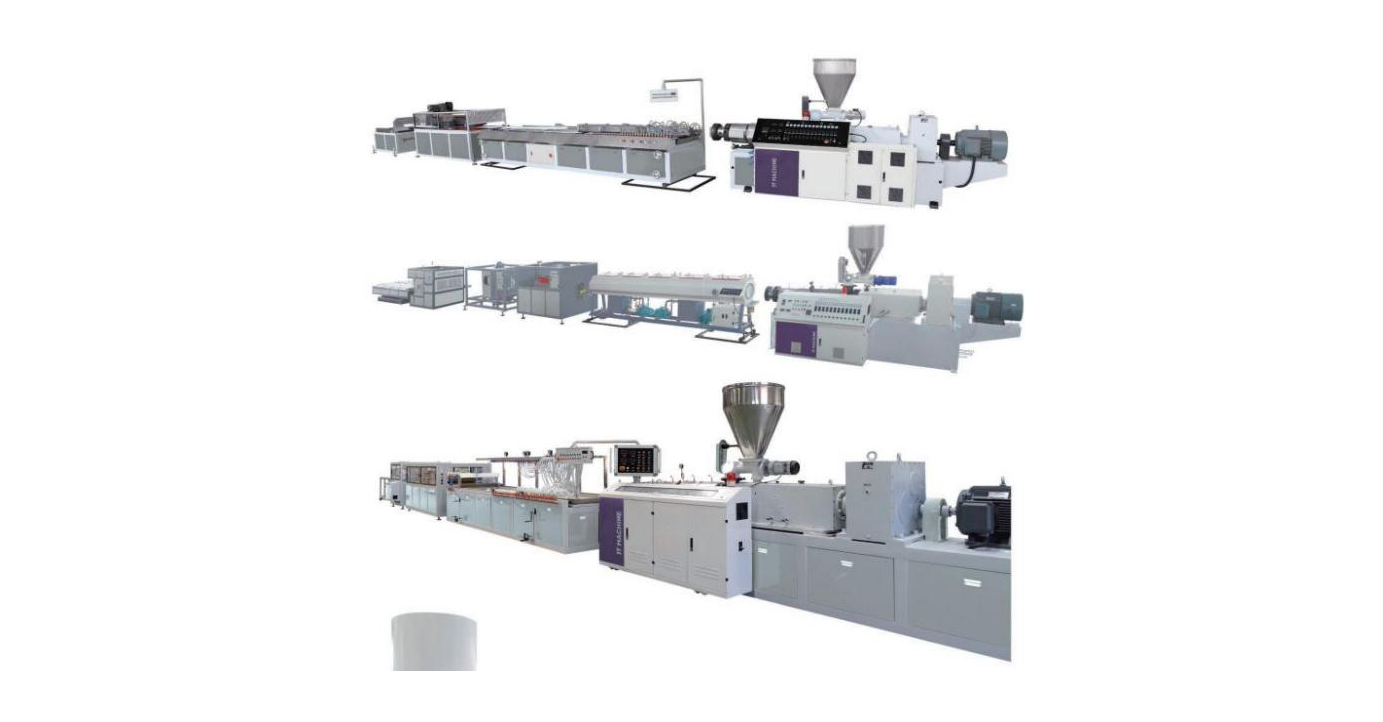

Types of extruders

Extruders can be divided into single screw, twin screw and multi screw extruder according to the number of screws. At present, the single screw extruder is the most widely used, suitable for extrusion processing of general materials. Twin screw extruder has less generate...Read more -

Hollow blow molding machine’s industry development

Blow molding machine is a very common mechanical equipment in the plastic machinery industry, and blow molding technology has been widely used all over the world. According to the parison production method, blow molding can be divided into extrusion blow molding, injecti...Read more