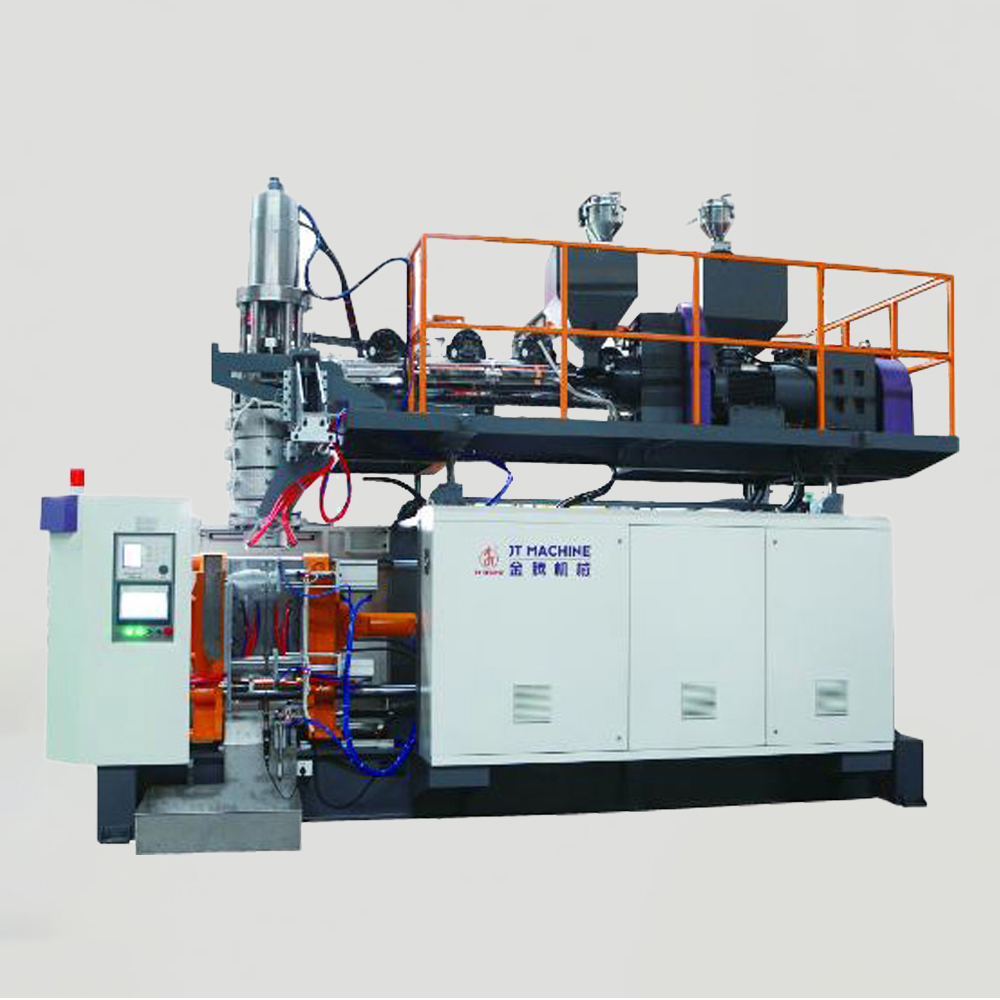

Bottle blowing machine

The hydraulic system adopts proportional technology to optimize the design of hydraulic oil circuit, with the characteristics of energy saving, fast action and convenient parameter adjustment.

Double proportional valve control oil flow rate and pressure, reversing valve control flow direction, deceleration valve brake, smooth and fast action. Automatic lubrication system, reduce equipment maintenance workload.

JT series bottle blowing machine is equipped with a drop-down width device, which can stretch the material pipe to both sides and then blow, making the bottle shape more even and full.

For the large diameter material pipe, the machine is equipped with preclamping bottle embryo device adhensive pipe mouth, so as to insert the pen and blow air .

Strengthen the hard cold processing screw , equipped with plastic mold head, double remodeling ,good plasticizingeffect, extrusion volume, screw barrel wear resistance.

The template center force design to ensure the uniformity of clamping force, with the linear guide made in taiwan, the movement of the formwork is faster and more stable and the clamping force is stronger.

The whole formwork system is made of ductile iron, which is stable and solid and durable without deformation. Using mainpulator to automatically take products, saving manpower, safety nd security.

Energy –saving power design: variable frequency motor is used to drive the screw, and the main hydraulic system is controlled by servoi motor, which is 15%-30% more energy –saving than ordinary motor drive, and cylinder drive is used for automatic overflow removal.